Aviation: Component and materials testing laboratory, EMC testing laboratory

Testing of components and assemblies in aircraft

We connect research and industry. We support our customers in the development and improvement of safety and availability of their products. Our competence lies in the operation of a component testing laboratory as well as an EMC laboratory. We offer the conception, execution and evaluation of complex mechanical and electronic tests on components and assemblies.

Goals

TÜV AUSTRIA Group meets the highest standards of safety and innovation to the same extent. Our tests and analyses make state-of-the-art technologies safe and competitive for the market. We guarantee this as an independent testing laboratory accredited according to EN ISO/IEC 17025.

Solution

Mechanical Testing

- Material and component testing, static and dynamic

- Fatigue testing up to full-scale components

- Multi-axial test field 13×20 m

- Tensile and compression testing up to 45 MN and 20m clamping length

- Torsion testing

- Fracture mechanic testing

- Chemical analysis

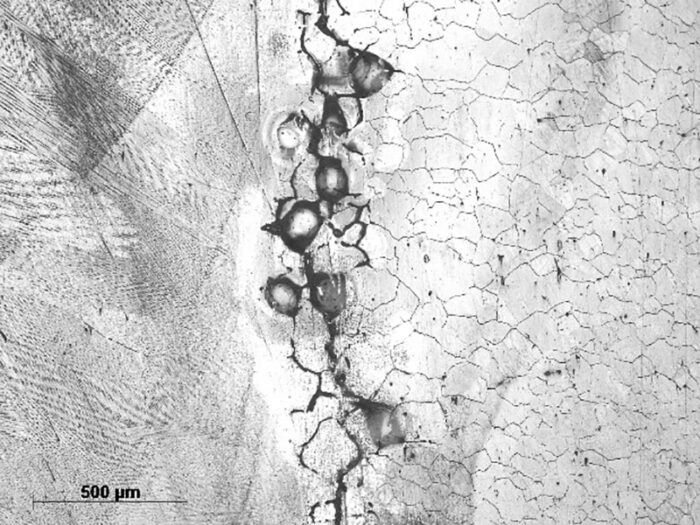

- Full metallographic analysis (REM/EDX)

- Corrosion testing

- Volatile Hydrogen measurement

- Climate chambers (10 m3, -40 °C to +90 °C, 95 % humidity)

- In-service measurement of force, displacement, acceleration, strain gauge 250+ channels

- Non-contact 3D strain measurement ARAMIS

- Tomography iCT, 225/450kV, voxel size 2 micron, specimen 200 kg 1100 mm x 1675 mm, in-situ load 5 kN 250 °C

- Damage analysis

Electromagnetic Compatibility | Electromagnetic Interference

- EMC and EMI services

- Semi-Anechoic Test chambers up to 13x10x6m/Quiet Zone Ø2m@3m and Ø6m@5m Measuring Distance/max 8t/Door 3mx3m

- Notified Body for EMC (EU-Directive 2014/30/EC) and RED (EU-Directive 2014/53/EC)

- Telecommunication Certification Body (TCB) – Federal Communications Commission (FCC) USA

- Conformity assessment body (CAB) – Innovation, Science and Economic Development (ISED) Canada

- Accredited test Lab for more than 500 EMC (EN, IEC, CISPR, ETSI, etc.) Standards, Radio Standards and Product Standards e.g.:

- RTCA DO-160G (Environmental Conditions and Test Procedures for Airborne Equipment)

- UN Vehicle Regulations – Regulation No. 10 – Rev.5 (Uniform provisions concerning the approval of vehicles with regard to electromagnetic compatibility)

- MIL-STD-461F (requirements for the control of electromagnetic interference characteristics of subsystems and equipment)

- NATO AECTP 500 (Electrical/Electromagnetic Environmental Tests)

Results

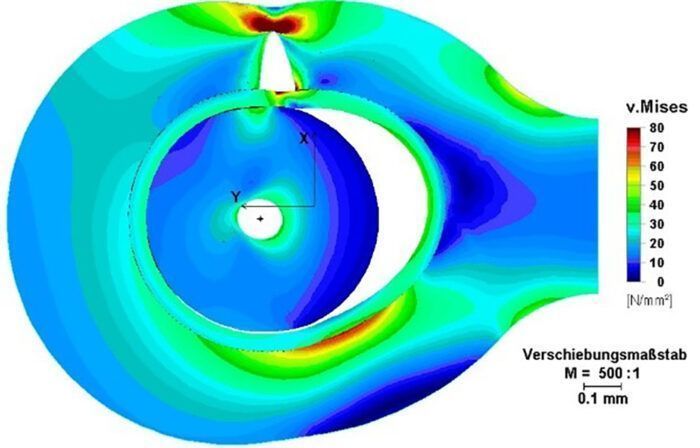

We carry out the tests according to your specifications on the components. We carry out all measurements, evaluate and document the results and combine them into reliable statements. Our tests make your development cycles faster, they follow the simultaneous engineering approach and bring your simulation and measured values in line.

Benefits for you

- Experience and competence in science, research and application for decades

- Flexible and efficient laboratory infrastructure with own workshops and measuring technology

- Carrying out dynamic component tests, multi-axis fatigue testing

- Material characterization and damage analysis

- Data for FEM, development support, simulation of extreme situations, load simulation over the entire service life

- Carrying out EMC measurements

- Approval of components/assemblies according to standards (mechanical+EMC)

TÜV AUSTRIA TVFA Prüf- und Forschungs GmbH

Phone: 43(0)1 6650 600

E-Mail: office@tvfa.at

Gutheil-Schoder-Gasse 17, AT-1230 Vienna